HOLCIM DUQUESNE SLAG PLANT

AIR COOLED BLAST FURNACE SLAG

From the World Leader in Construction Materials

Air Cooled Blast Furnace Slag (ACBFS) - An environmentally friendly alternative to mined aggregate, offering superior performance, substantial savings, and excellent value.

What is Air Cooled Blast Furnace Slag?

Air Cooled Blast Furnace Slag (ACBFS) is a versatile construction aggregate that provides superior compaction and skid resistance plus cost savings over mined aggregate.

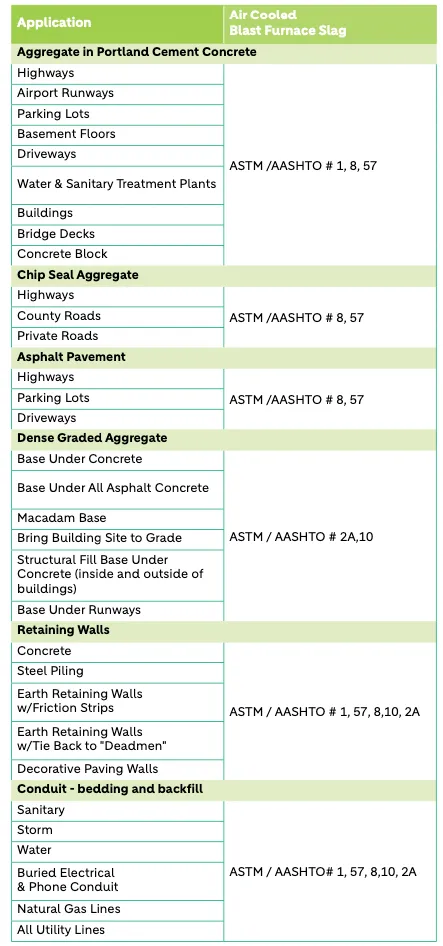

It can be safely used in a variety of applications including concrete, asphalt, sub-base, bedding, and backfill.

Duquesne Slag Operations

890 Noble Drive West Mifflin, PA 15122

412-461-1163

Contact Our Team

Matt Smith

matthew.smith1@holcim.com

412-526-2970

Paul Thomas

p.thomas@holcim.com

412-452-2772

Blast Furnace Slag is produced to meet state specifications for gradation and other key requirements.

The American Society of Testing and Materials (ASTM C-125, Definition of Terms Relating to concrete and concrete Materials) defines Blast Furnace Slag as “the non-metallic product consisting essentially of silicates and aluminosilicates of calcium and other bases, that is developed in a molten condition simultaneously with iron in a blast furnace.”

Air Cooled Blast Furnace Slag is the mineral which results from the reaction of limestone (high calcium) and dolomite (high magnesium) with earth metals in iron ore in a blast furnace. It is the co-product of iron manufactured in a blast furnace.

Air Cooled Blast Furnace Slag is the material resulting from the solidification of molten blast furnace slag under atmospheric conditions, subsequent cooling may be accelerated by the application of water to the solidified surface.

Air Cooled Blast Furnace Slag aggregate is created by crushing, screening and washing the blast furnace slag into specification aggregate sizes.

Air-Cooled Blast Furnace slag is non-expansive as tested in accordance to PennDOT PTM130.

PennDOT, Pennsylvania Turnpike, WVDOT, ODOT Approved Air Cooled Blast Furnace Slag undergoes a sulfur leachate test in accordance of Ohio DOT Supplemental 1027 to ensure the material is ecologically benign for use in unencapsulated applications. #1, #8, #10, #57, and #2A Slag is available for these applications once it has been tested and approved in collaboration with the Pennsylvania Department of Transportation, Pennsylvania Turnpike Commission, West Virginia Department of Transportation or the Ohio Department of Transportation.

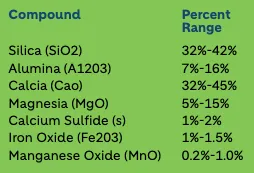

Chemical Properties

The principal constituents of slag are silica, alumina, calcia and magnesia, which comprise 95% of slag’s total make-up. Minor elements include manganese, sulfur and ferrous compounds as well as trace quantities of several others. The compounds do not occur as oxides in the slag but are combined to form various silicate and aluminosilicate minerals such as melilite (2CaO. A1203.SiO2 and 2 Cao. Mg0.2SiO2), merwinite (3CaO. Mg0.2SiO2), wollastonite (aCaO.SiO2), etc., as found in natural geological forms.

Features and Benefits

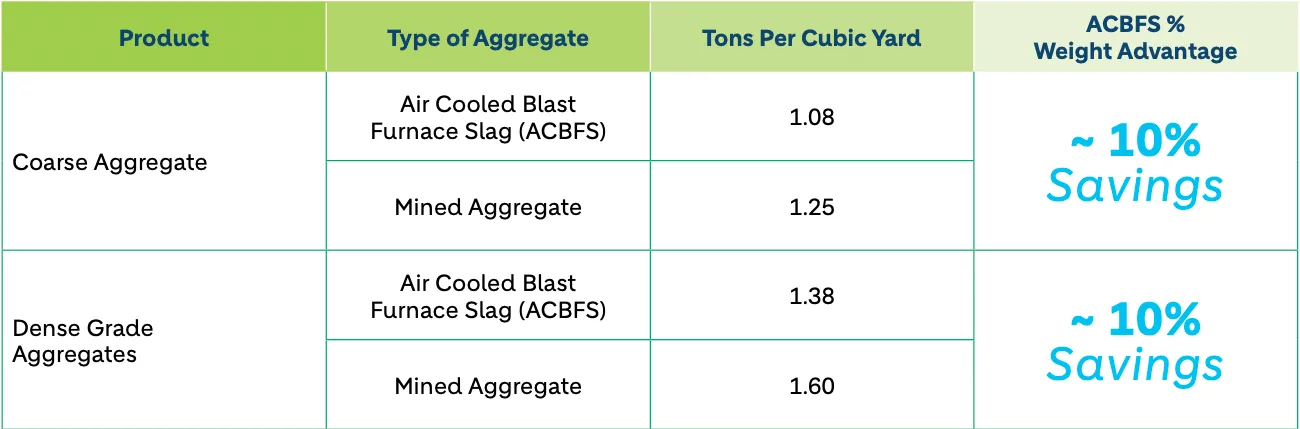

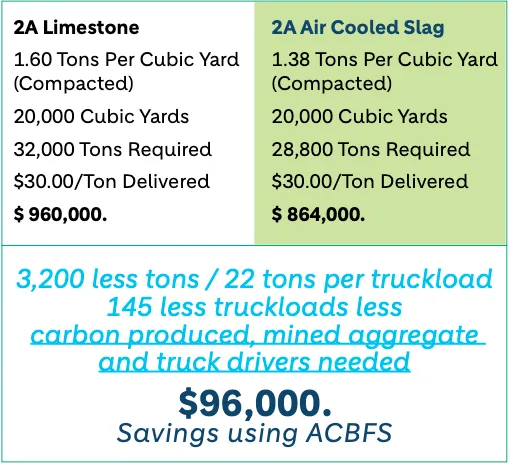

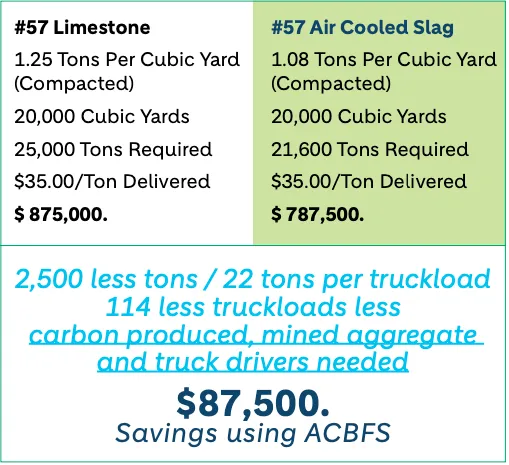

Weight Advantage

Air Cooled Blast Furnace Slag weighs less per unit volume than mined (limestone, sand & gravel) aggregate...

...translating into significant sustainability and cost savings for contractors when they use Air Cooled Blast Furnace Slag.

These are examples only - actual delivered pricing will vary.

Test Results

- #1 Gradation Test Results

- #8 Gradation Test Results

- #8 Sheer Test Results

- #57 Gradation Test Results

- #57 Sheer Test Results

- 2A Gradation Test Results

- 2A Sheer Test Results

- Duquesne Penndot Bulletin 14 Chart

- Dusquesne ACBFS WGM0144 Test Results

- Oxides and Carbon Test Results

- PennDOT PTC Projects.pdf

- PTM130 Expansion Test Results

- Sulfate and Leachate Test Results

- Coproduct Determination

The Circular Economy

DRIVING CIRCULAR CONSTRUCTION TO BUILD BETTER WITH LESS

As a world leader in recycling, Holcim is committed to building better with less and preserving the earth’s ecosystems. We promote circularity along the entire value chain to eliminate waste and decouple our business growth from the consumption of finite natural resources.