Building Better with Less to Decarbonize Construction.

Carbon capture has the potential to greatly reduce embodied carbon in the building sector. Holcim US is exploring Carbon Capture Utilization Storage (CCUS) solutions, and committed to helping accelerate this new technology.

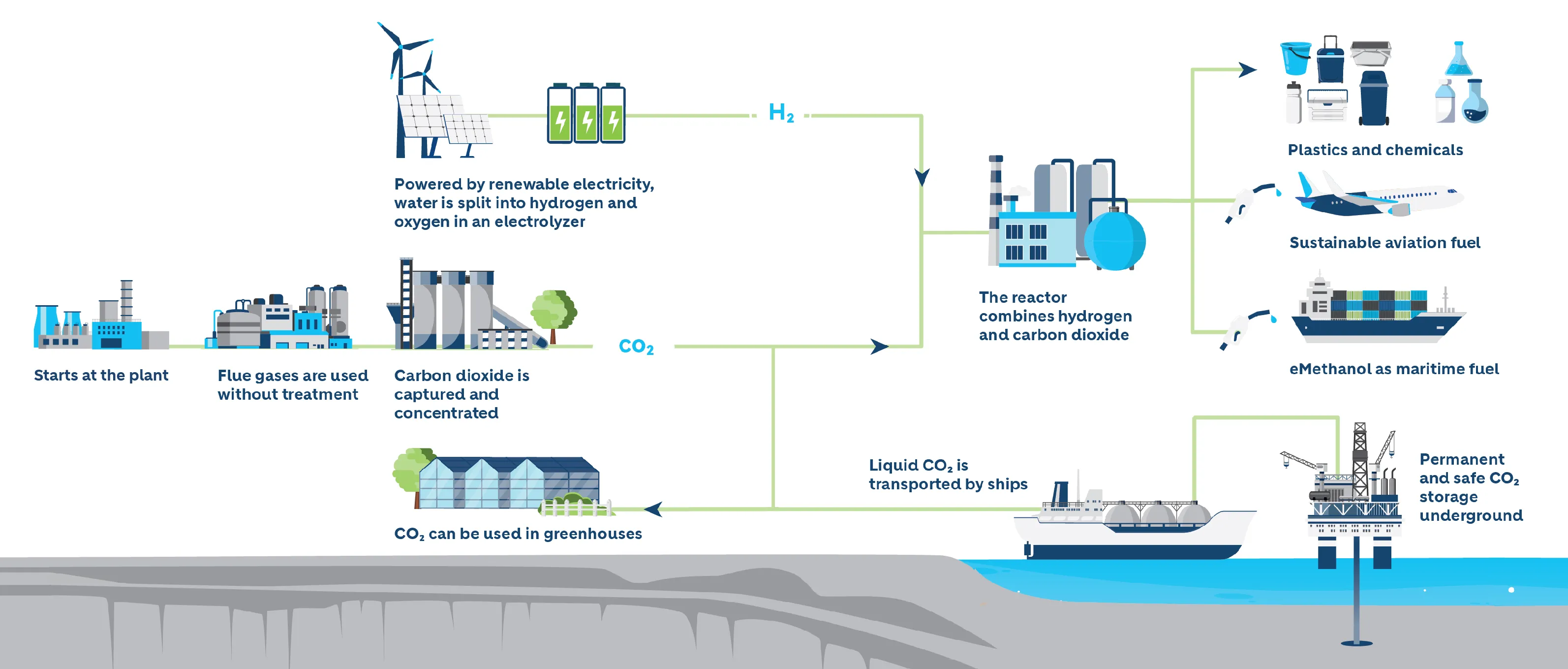

CCUS systems capture CO2 gas created during the cement manufacturing process, then compress it into a liquid that is transported deep underground for safe long-term storage. Carbon capture is one of the only available processes that can directly reduce current carbon emissions at the source, where CO2 is most easily removed.

Next-generation technologies

Around the world, Holcim is preparing for the future by developing next-generation technologies to accelerate our net-zero journey around the world.

We are actively exploring the potential of carbon capture, utilization and storage (CCUS) with over 30 pilot projects ongoing around the world. Our projects range from recycling CO2 from our plants into low-emission raw materials for our green cement, all the way to using it as a greenhouse gas for farming or as a source of methanol for aviation fuel.

Working with a range of partners from start-ups to academic institutions, we are also developing breakthrough technologies like magnetizable concrete to enable roads to charge electric cars while in motion.

“Our commitment to sustainability motivates us to take critical steps to continually move toward a net-zero future, creating value for our company, our business and the world.”

Partnerships lead to CCUS innovations

Holcim US partnered with US Department of Energy (DOE) to develop CCUS systems at their Ste. Genevieve, MO and Portland, CO cement plants. Combined, the two projects have the potential to prevent the release of 4.5M metric tons of CO2 per year.

Through the Better Climate Challenge, DOE is working with leading organizations, across the US economy, to set ambitious, portfolio-wide, and near-term operational greenhouse gas (GHG) emissions reduction goals and to demonstrate how leaders are measurably taking steps to address climate change.

Holcim US partnered with Solidia Technologies to develop a reduced-carbon cement using carbon capture technology. As a result, national landscape chain EP Henry introduced a new line of pavers using Solidia® Cement

Low-Carbon Products

Our clients are looking for more sustainable products and Holcim US provides several reduced and low-CO2 options for blended cement and concrete.