THE CHALLENGE

- The project team needed to come up with ideal sustainable concrete solutions for the wide range of construction applications.

- With the job site located on one of the busiest thoroughfares in Boston, logistical problems needed to be addressed to ensure continuous on-time deliveries from off-site concrete batch plants.

- With concrete representing a significant portion of the structure, the use of eco-friendly, high-performance mixes was paramount to minimize the environmental footprint.

THE SOLUTION

- This project was ideal for ECOPact green concrete—the industry’s broadest range of low-carbon concrete mixes for high-performing, sustainable, and circular construction.

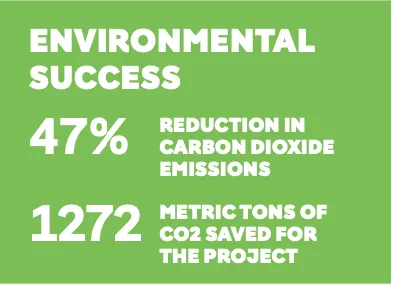

- For the mass concrete foundations pour, 4,200 cubic yards of ECOPact were delivered over a span of 15 hours—totaling 711,000 kilograms of CO2 reductions.

- The team partnered with the client and developed two proprietary ECOPact design mixes containing 20 percent recycled materials.

- These innovative mixes were designed to reduce the global warming potential (GWP) by 35 to 50 percent compared to standard concrete.

- The project’s AgileFlow mixes used an innovative cement blended with Silica Fumes. These self-consolidating mixes helped optimize jobsite concrete placement, while also providing a 24% CO2 reduction compared to a standard concrete baseline.

“With innovative product and digital process solutions, the project team was able to successfully execute one of the largest and most sustainable pours Holcim has ever done.”

| Sales manager for Holcim - Northwest Region, Inc.

Download the Fact Sheet

Download the Case Study

ECOPact low-carbon concrete

The industry’s broadest range of green concrete with 100% performance offering at least 30% lower CO2 emissions compared to standard (CEM I/OPC) concrete.