THE CHALLENGE

- A 42-story, Art Deco inspired concrete structure, the project required concrete to be poured and vertically pumped in widely varying temperature conditions.

- Client had strict requirements for modulus of elasticity - measure of building stiffness - to limit sway of the tall, slender structure.

- Small site created logistical challenges for product delivery.

THE SOLUTION

- The height and aesthetics of the tower demanded technical leadership and high-performance concrete solutions including DYNAMax for high-strength, durability and rigidity and RAPIDFORCE high-early strength for quick-setting.

- Project utilized 37,000 total cubic yards of concrete. 6,000 psi and 8,000 psi strengths used for post tensioned decks while 10,000 psi and 12,000 psi implemented for walls and columns.

- To achieve the desired modulus of elasticity, granite was used as the aggregate in 10,418 cubic yards of DYNAMax mixes and stringent quality control efforts achieved desired results.

- For mass concrete foundations pour, 1,168 cubic yards of ECOPact Prime was used, providing a 50% reduction in CO2 emissions when compared to traditional concrete. This mix also helped control the temperature supporting proper curing of the concrete.

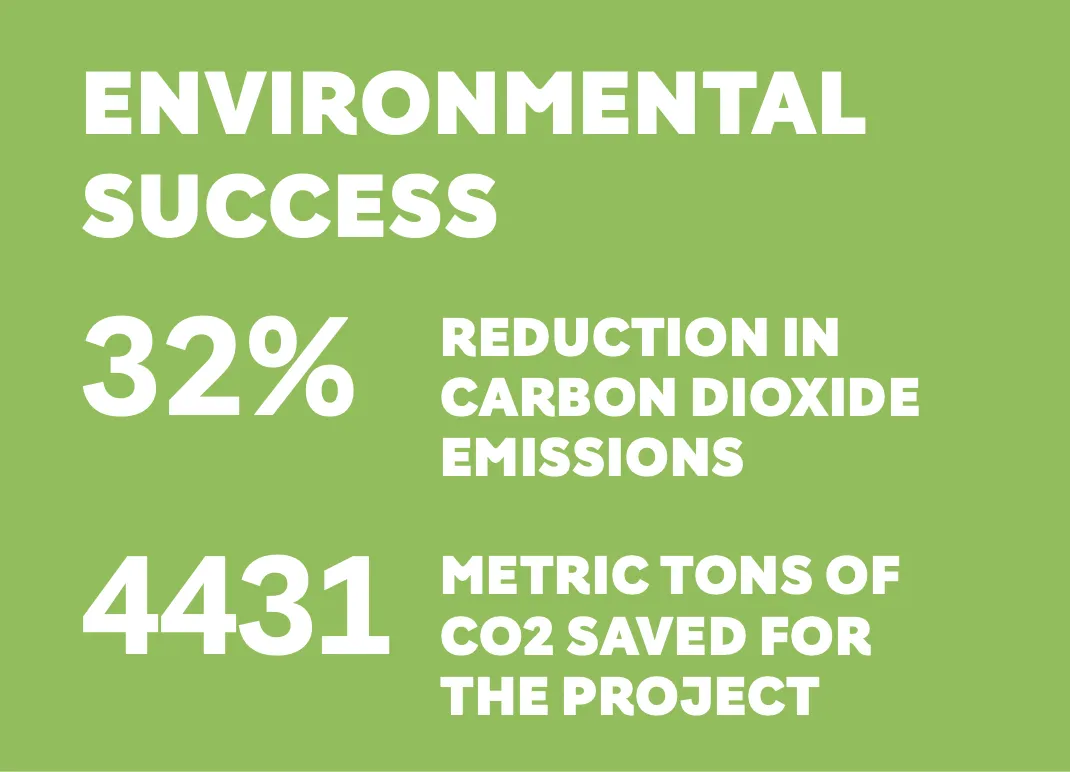

- Over 9,000 cubic yards of ECOPact low-carbon concrete was used in the project, providing a 32% reduction in carbon emission when compared to traditional concrete.

- Strategic planning and continuous quality control allowed concrete to be poured and pumped vertically through different, sometimes extreme weather conditions ranging from summer heat to winter cold.

- Extensive logistics and staging coordination ensured continuous, on-time product delivery.

ECOPact low-carbon concrete

The industry’s broadest range of green concrete with 100% performance offering at least 30% lower CO2 emissions compared to standard (CEM I/OPC) concrete.