Cement Solidification and Stabilization: Solutions for Managing PFAS Contaminated Soils and Landfill Leachates

Today, everyone is hearing or reading about perfluoroalkyl and polyfluoroalkyl substances—often referred to as “PFAS.” Since the 1940s, this group of several thousand synthetic chemicals has been used in an array of industrial and commercial products—from nonstick cookware and food packaging to stain-resistant carpets and artificial turf. In addition to applications that are familiar to consumers, PFAS are also components of Class B (flammable liquid) firefighting foams, known as aqueous film forming foams (AFFF), that are used to extinguish hazardous fires at airports, military bases and industrial plants.

Over the years, PFAS compounds have taken on the label of “forever chemicals” because they break down very slowly over time due to their ultra-strong carbon-fluorine bonds. Their widespread use and persistence in the environment, coupled with their mobility, toxicity, and potential to bioaccumulate, have sparked heightened consumer anxiety nationwide. As more and more of these substances are found in water, air and soil, regulatory scrutiny of these hazardous chemicals is increasingly intensifying.

Current Regulatory Landscape

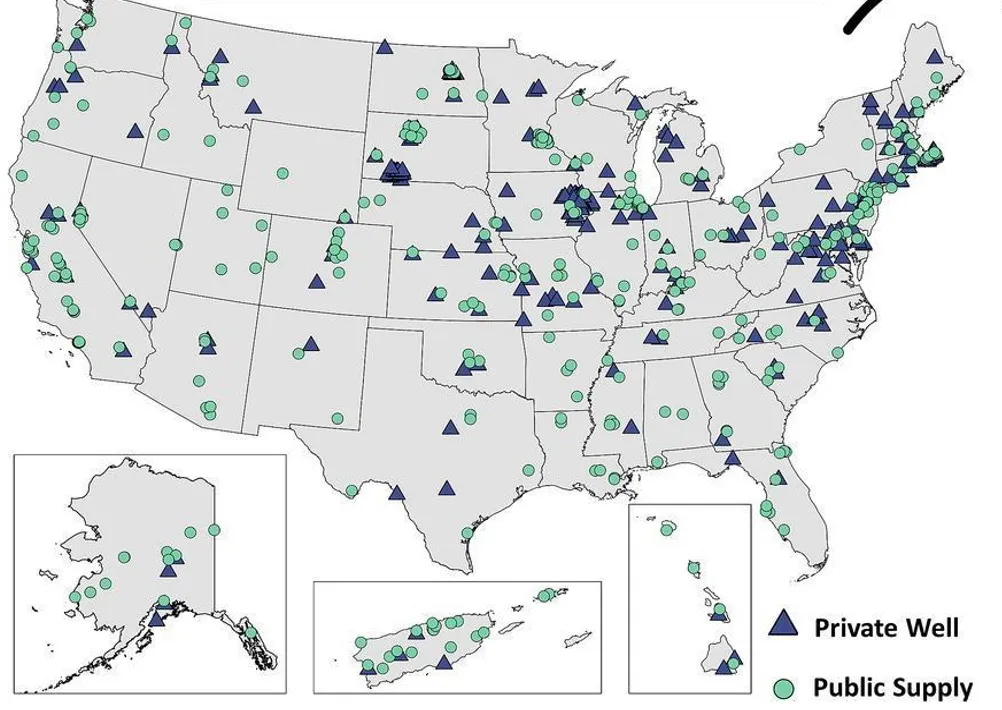

Studies have shown that nearly half of U.S. drinking water supplies contain at least one form of PFAS.1 As part of a nationwide effort to confront the problem, the Bipartisan Infrastructure Law is investing $5 billion to help communities reduce PFAS in their drinking water. Government regulatory agencies are also taking action by setting strict limits for certain PFAS compounds in water supplies and accelerating the remediation of contaminated sites.

In 2021, the U.S. Environmental Protection Agency (EPA) released a PFAS strategic roadmap,2 which includes efforts to set a national drinking water standard for PFOA (perfluorooctanoic acid) and PFOS (perfluorooctanesulfonic acid). It has also proposed designating these two PFAS chemicals as hazardous under the Superfund law and setting legally binding limits of four parts per trillion or less in drinking water. In March 2023, the agency further proposed new national drinking water contamination limits for four additional PFAS: PFNA, PFHxS, PFBS and GenX (a shorter carbon chain replacement of PFOA). The EPA anticipates that all these proposed PFAS regulations will go into effect by the end of 2023.

The regulatory landscape surrounding PFAS is complex and quickly evolving. Many state and municipal governments have established their own standards and regulations on PFAS, which may set even more stringent maximum contaminant levels in local drinking water supplies.

A Daunting Remediation Challenge

Given the prevalence of PFAS in the environment, there is a tangible risk that almost every site tested will be found to exceed some of the acceptable regulatory limits. To date, the focus has been on military bases, airports, landfills, manufacturing sites and water supplies. As many of these primary sources are investigated, attention will shift to secondary sites where PFAS have been used—and increasingly to brownfield sites in urban areas.

Even though some PFAS compounds are highly leachable and travel significant distances, they persist within source areas decades after being released. Unlike many other contaminants, these hazardous chemicals are difficult to destroy, which makes cleanup a complex task. While different remediation approaches have been developed, the effectiveness, cost and overall value of these technologies range greatly.

Cement solidification/stabilization (S/S) is a well-established treatment approach that offers an effective, more economically viable option for managing PFAS-impacted soils, sludges, dredge spoils and landfill leachates. While cement S/S does not destroy the contaminates, it keeps them from leaching above safe levels into the environment. Tailored site-specific solutions effectively sequester and reduce the mobility of all types of PFAS, as well as the movement of water through the solid matrix. This all-encompassing encapsulation of hazardous compounds, including persistent, hard-to-treat contaminates in low concentrations, can eliminate the pathway to exposure.

Designing a Tailored Solution

Cement S/S is highly effective in immobilizing contaminates because it reduces hydraulic conductivity and aqueous solubility. Solidification physically binds and entraps contaminants in a solid matrix that—compared to untreated soil or sediment—is stronger and less permeable to water. Stabilization involves a chemical reaction that converts soluble hazardous constituents to insoluble forms, which results in a reduction in mobility and toxicity. Solidification and stabilization are often deployed together to prevent leaching of both harmful organic chemicals, such as PFAS and PCBs, and heavy metal contaminants, such as lead and cadmium, into groundwater.

PFAS remediation challenges are unique from site to site, owing to the sheer diversity of different PFAS constituents, coexisting contaminants, and other local soil or sediment conditions. Addressing this complexity requires a rigorous investigative process of characterizing the site-specific PFAS materials and competing contaminants that are present, analytical bench testing of various treatment formulations, pilot studies to evaluate results in real-world conditions, and finalizing the optimal S/S solution for meeting specified performance criteria, sustainable development ambitions, and cost-efficiency goals.

Because of the vast types of hazardous PFAS compounds, the binder mix design is extremely important in limiting the leaching potential of contaminants to extremely low values. Although remediation can be completed with standard portland cement alone, most tailored, site-specific S/S solutions rely on a custom blend of supplementary cementitious materials to maximize performance, sustainability, and cost benefits.

S/S of PFAS Contaminated Soil

Cement-based S/S is widely used in the remediation of abandoned or under-utilized brownfield properties that are exceedingly difficult to redevelop due to soil contamination. From a sustainability perspective, the cleanup and redevelopment of these sites with S/S methods constitute 100% resource recovery as the cement-treated contaminated soil can be recycled into a foundation material for future structures built on the property. For this reason, the LEED program rewards projects that use S/S to rehabilitate brownfield sites with credits toward certification.

Two different S/S application methods—in-situ and ex-situ—have been devised for remediating contaminated sites. Both approaches have proven to be highly effective in solidifying the soil and preventing hazardous PFAS compounds from leaching into groundwater. The hydraulic conductivity of the cement-treated land is typically on the order of 10-7 cm/sec or less, allowing for the effective encapsulation of all contaminants and permanently isolating them from the environment.

In-Situ S/S Method

With the in-situ method, contaminated soil is treated directly in place (see Figure 2). Numerous types of mechanical devices have been used successfully in this manner. Some high-tech systems precisely meter binder and water into the mixing zone using an on-board computer and global positioning controls. Other systems are no more precise than a backhoe mixing cement into the soil until mixing is complete.

One approach is to use an auger and excavator or a modified excavator with a rotating drum to homogenize the soil with a slurry of cementitious product, which is injected directly into the mixing zone through nozzles at the bottom of the augers as they turn. Another approach is grout injection, which uses high pressure to force the binder into the soil pore space through grout injection pipes. Both techniques can be used to treat media as deep as 60 feet below the ground surface.

Shallow contamination can be treated using common excavation equipment, such an excavator and bucket to mix in the reagents at the surface. More specialized excavators equipped with forks, injection nozzles, and high-speed rotary blenders to facilitate mixing of the binder and contaminated media can also be used. These shallow mixing techniques generally are applicable to a maximum depth of about 10 to 15 feet.

S/S has been used successfully at countless contaminated sites across the U.S., making the soil safe and usable again. One of the most compelling advantages to in-situ S/S is the expense, which is typically half that of other remediation options. While the effectiveness of alternative remediation technologies varies, most require the costly excavation of the contaminated soil, treatment, and disposal of the treated material in a landfill, as well as the placement of clean materials to backfill the excavation.

Ex-situ S/S Method

Ex situ S/S is performed by excavating the soil or sediment, separating out debris, and then thoroughly blending the soil with the cementitious binding agents in a mechanical mixing device, such as a rotary drum or pug mill. The treated soil is then either placed back into the ground from where it was removed, used as a fill material at another site, or disposed of in a landfill. Typical ex-situ remediation operations are shown in Figure 3.

The ex-situ S/S method is often used when the contamination at a site is deeper than 25 feet. As a result, the soil is treated in lifts. The top 20 feet of soil is removed and treated in a pug mill and stockpiled. The deeper material is then excavated and treated ex-situ. The treated soil is then placed back in the ground, reused in some other fashion, or disposed of in an off-site landfill.

An important advantage of ex-situ applications is that the contaminated soil and binder can be metered together very accurately, which optimizes the amount of binder needed for effective remediation. In addition, the ex-situ S/S method usually can process a larger amount of soil in a shorter amount of time than in-situ methods, depending on the size of the pug mill or other mixing device.

The ex-situ method is often more expensive, however, than in-situ treatment applications due to excavation requirements, ancillary equipment needed to process the soil, and the need to place the treated soil back into the site or transport it to an offsite landfill. It also requires a larger footprint for the equipment.

Former Military Base Example

Class B firefighting foams (AFFF) used at aviation facilities, including U.S. Department of Defense (DOD) sites, are considerable sources of PFAS released to the environment. While awaiting the promulgation of EPA standards to guide remediation actions, the DOD is performing PFAS contamination assessments at more than 700 military installations where AFFF have been used. Strategies for addressing contamination at these sites are not yet well established and, as such, the DOD is proactively collaborating with universities, consultants, and technology companies to help evaluate and develop a systematic treatment approach. Holcim US is actively involved in many of these site assessments and research efforts to demonstrate the effectiveness of S/S in encapsulating the PFAS contaminated soil in place.

In 2021, Holcim US was engaged in a project with a major research university to determine the potential applicability of in-situ S/S for the encapsulation of PFAS from AFFF used at a former DOD airfield. The treatability study was completed in two phases by creating several binder formulations to determine the most effective mix. In the first phase, eight binder mixes were investigated in four different soil samples collected from the site. These were subjected to the structural integrity test outlined in EPA 1310b and then evaluated for total PFAS by three extraction methods (MeOH, SPLP and TCLP).

Although SPLP (the most “real world” extraction method) results revealed significant reductions in leaching potential from the stabilized matrix, it was decided to investigate nine additional binder mixes with engineered controls in the second phase of the study. The performance of the mixes in the second phase of the study showed significant reductions in the leachate concentrations of PFAS congeners in the soil (see Table 1). These results demonstrate that in-situ S/S can cost-effectively sequester PFAS within a stabilized soil matrix and can be considered as a viable remediation solution for contaminated sites.

Former Industrial Site Example

Cement S/S—an EPA “Best Demonstrated Available Technology” for more than 50 Resource Conservation and Recovery Act (RCRA) listed wastes—has been used for more than 40 years to encapsulate hazardous compounds in contaminated soils at Superfund and brownfield sites throughout the U.S. In Michigan, the Department of Environment, Great Lakes, and Energy (EGLE), formerly the department of environmental quality, is working to identify brownfield locations where PFAS may be present and implement practical and cost-effective solutions to remediate the contamination problems.

In the Fall of 2022, Holcim US collaborated with one of the nation’s largest environmental remediation firms to complete a field trial on the effectiveness of custom-designed S/S treatments in reducing the leachability of PFAS in contaminated soils at a brownfield site in-situ. The long-abandoned industrial property contained multiple acres of soil with PFAS contamination up to 20-feet deep. The goal of the study was to demonstrate to EGLE the effectiveness of various amounts of custom-designed Holcim mixes for encapsulating the PFAS in the soil. The leachate in the encapsulated soil would need to meet groundwater standards for both PFOA and PFOS.

The field trial was completed by year-end 2022 and demonstrated that PFAS-contaminated soil in place, left in place, effectively prevented leaching of contaminants into groundwater. Results were promising as all soils were responsive to treatment.

Encapsulation of PFAS in Landfill Leachate

Due to widespread use and disposal through typical waste management pathways, PFAS-containing wastes are currently managed through containment in landfills. Landfill leachate—the liquid effluent formed by rainwater percolating through waste—often contains high concentrations of PFAS. Unlined impoundments or landfills with liners that fail can release PFAS-containing leachate and contaminate groundwater.

Ideally, contaminated leachate is removed from the bottom of the landfill and treated to prevent the migration of PFAS. A common approach is to send the extracted leachate to publicly owned treatment works (POTWs), most of which do not have the capabilities to effectively treat or control PFAS-containing leachate. As such, some POTWs are requesting landfill operators to pretreat the leachate on-site and some are implementing surcharges based on the leachate quality. Other sites recirculate the leachate back into the landfill.

There are a variety of on-site management approaches but only a few—such as thermal treatment, foam fractionization, and reverse osmosis—have demonstrated the ability to provide significant removal of PFAS from landfill leachate. These removal technologies reduce the treatment volume by concentrating rather than destroying PFAS, which leaves a residual that must be managed. One promising management approach involves the application of a tailored site-specific cement-based S/S treatment program to encapsulate the contaminants and cost-effectively return the treated concentrate to the landfill, dramatically reducing the availability of PFAS to the environment.

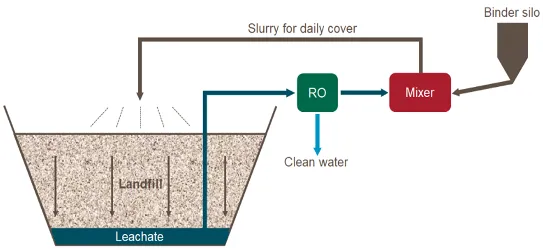

In 2018, Holcim US embarked on an extensive research project to develop proprietary product mixes to reduce the leachability of PFAS from reverse osmosis (RO), thermally treated, and foam fractionated concentrates and allow the treated slurry to be sprayed onto the surface of the landfill as an alternate daily cover (ADC). All Landfills are required to have a daily cover. This is often accomplished by using six inches of dirt. The in-depth scientific investigation resulted in a Holcim-patented method that reduces the ADC depth to one inch or less, extending the life of the landfill. A simplified schematic of the leachate treatment process utilizing an RO system is shown in Figure 4.

The new S/S methodology process for the remediation of PFAS in landfill leachate epitomizes sustainability as it constitutes 100% resource recovery and eliminates the endless cycle of recirculation of PFAS contaminated leachate into the landfill or going from landfill to POTW and back again. Completed and on-going S/S bench and pilot testing on concentrates are very encouraging with typical results (Table 2) showing reduced leachability of PFAS by two to five orders of magnitude compared to the initial amounts in the leachate concentrate. This process of forming an ADC has been approved by the State of Michigan at a landfill.

Landfill Leachate Treatment Example

Holcim US is conducting bench testing and field trials at sites throughout the country to continue the development of formulations for encapsulation of PFAS contaminated leachate, which enables the treated material to be beneficially used as a daily cover for a landfill. To date, test results for this cement encapsulation technology are very encouraging for successful deployment at landfills.

In one investigative study, Holcim US evaluated more than 40 formulations of cement blends for reducing the leachability of PFAS from RO-generated concentrate and lowering the cost of managing PFAS. As landfill leachate passes through an RO system, selective membranes generate a purified permeate that passes through the filters and a concentrate of all contaminants, including PFAS that does not. RO and other technologies can typically achieves up to 99% removal of PFAS according to the EPA.3

The intent of the landfill leachate project was to develop the ideal site-specific solution that would achieve the following goals: 1) no free liquids in less than 24 hours; 2) a reduction in the leachability of PFAS from the treated concentrate by at least two orders of magnitude; and 3) a treated hardened concentrate that can be used as ADC for reducing landfill material management costs.

Five samples of concentrate treated with various Holcim mix designs were submitted to an independent laboratory for SPLP extraction analyses on fourteen PFAS compounds, including PFOA and PFOS. In all cases, the concentrations of PFAS in the treated leachate concentrate were at least two orders of magnitude less than the total amounts reported in the “as is” pre-treatment samples. The detection level for PFAS in the SPLP extracts was quite low (1.9 ng/L- 3.8 ng/L) or, in many cases, not detected at all. These results enable an onsite ADC alternative for cost-effectively managing leachate concentrate at the landfill rather than hauling or pumping it offsite.

Holcim Can Help

Holcim US has a long history of developing cost-effective and reliable S/S solutions for meeting a wide range of site remediation challenges involving metals and organic contamination. Our strength is centered on our understanding of complex contaminate chemistry and regulatory standards, our in-depth knowledge of how local site conditions and cement work together, and our full portfolio products for tailoring the optimal site-specific S/S treatment program.

Contact your sales representative to learn more about the ways we can help you succeed with cement S/S for remediating PFAS in contaminated soils and landfill leachates. The key to success is to leverage our expertise by engaging with Holcim’s qualified professionals early in the planning process to discuss your project goals, initiate testing, and customize a tailored solution to ensure a high level of performance.

References

- K.L Smalling, et. al.; U.S. Geological Survey; “Per- and polyfluoroalkyl substances (PFAS) in United States Tapwater: Comparison of Underserved Private-Well and Public-Supply Exposures and Associated Health Implications”; Environment International; Volume 178, August 2023.

- “PFAS Strategic Roadmap: EPA's Commitments to Action 2021-2024”, October 2021, USEPA, https://www.epa.gov/system/files/documents/2021-10/pfas-roadmap_final-508.pdf.

- “Multi-Industry Per- and Polyfluoroalkyl Substances (PFAS) Study – 2021 Preliminary Report”, USEPA, September 2021, https://www.epa.gov/system/files/documents/2021-09/multi-industry-pfas-study_preliminary-2021-report_508_2021.09.08.pdf.

EXHIBITS (figures and tables)

Figure 1. PFAS detections in tap water from public-supply and private-wells (Source: US Geological U.S. Geological Survey).

Figure 2. Site using in-situ cement stabilization of contaminated soils.

Figure 3. Ex-situ mixing of cement with contaminated soils.

Figure 4. Leachate treatment overview.

Table 1: Military Base In-Situ Soil Sample Analytical Results

Table 2: Sample Results of Treated Leachate